Introduction To Some Models

Specifications

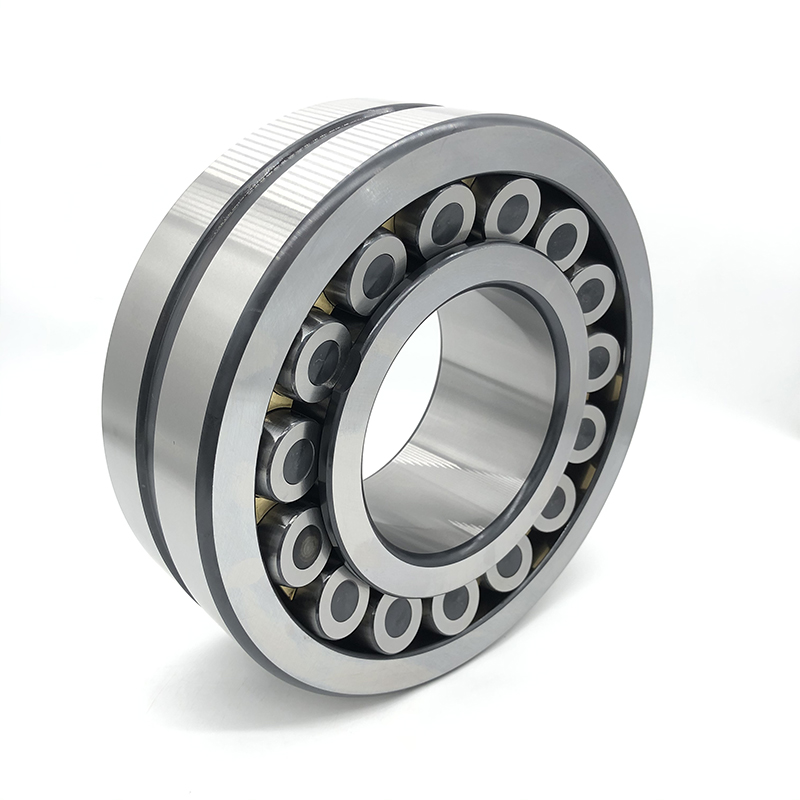

Product Display

Papermaking machinery, speed reducer, **** vehicle axle, bearing seat of rolling mill gear box, rolling mill roller, crusher, vibrating screen, printing machinery, woodworking machinery, various industrial speed reducers, vertical self-aligning bearing with seat.

Papermaking machinery, speed reducer, **** vehicle axle, bearing seat of rolling mill gear box, rolling mill roller, crusher, vibrating screen, printing machinery, woodworking machinery, various industrial speed reducers, vertical self-aligning bearing with seat.Product Introduction

MB bearing belongs to the self-aligning roller bearing series, which adopts brass retainer. The main applicable retainers are: stamped steel plate retainer (suffix E), glass fiber reinforced polyamide 66 retainer (suffix TVPB), machined brass solid retainer (suffix M) and stamped steel plate retainer (suffix JPA) in vibration situations. Self-aligning roller bearings have double rows of rollers, the outer ring has a common spherical raceway, and the inner ring has two raceways which are inclined at an angle with respect to the bearing axis. This ingenious structure makes it self-aligning, so it is not easily influenced by the angle of the shaft and the bearing box seat on the error or shaft bending, and it is suitable for the occasion of angle error caused by installation error or shaft bending. The bearing can not only bear radial load, but also bear axial load in two directions.Main Uses

Self-aligning roller bearings have cylindrical bore and conical bore, and the taper of conical bore is 1: 30 and 1: 12. This kind of conical bore bearing can be easily and quickly assembled on the optical axis or stepped machine shaft with the fastening sleeve or dismounting sleeve. The models of self-aligning roller bearings are: self-aligning roller bearings (type 20000CC); Tapered hole self-aligning roller bearing (20000CCK type); Self-aligning roller bearing (20000CC/W33 type); Tapered hole self-aligning roller bearing (20000CCK/W33 type); Self-aligning roller bearing (20000CCK H type) installed on the tightening sleeve; There are 6 kinds of self-aligning roller bearings (20000CCK/W33 H type) installed on the sleeve. The tapered hole self-aligning roller bearing with rear code K and K,K30 is installed on the matching fastening sleeve, which will become the rear code K H and K30 H bearings. This kind of bearing can be installed on the optical axis without shoulder, which is suitable for the occasion where the bearing needs to be installed and disassembled frequently. In order to improve the lubrication performance of the bearing, the outer ring of the bearing is provided with an annular oil groove and drilled with three evenly distributed oil holes, the rear code of which is W33.Main Applicable Cage

Stamped steel plate reinforced cage (suffix E, few in China). Stamped steel plate cage (suffix CC), glass fiber reinforced polyamide 66 cage (suffix TVPB), machined brass two-piece cage (suffix MB). Machining brass integral cage (suffix CA), stamping steel plate cage (suffix JPA) in vibration situations. Vibration occasion brass cage (suffix EMA). In the same structure, the codes on the bearings may be different.